Físico-química

PROPRIEDADES TECNOLÓGICAS & FUNCIONAIS DE PROTEÍNAS ALIMENTARES

As proteínas lácteas representam cerca de 30% do total de proteínas da dieta de adultos de países ocidentais. Embora essas proteínas no seu estado nativo tenham como uma de suas funções o transporte de moléculas, elas estão presentes nos alimentos em diversos estados estruturais, reflexo da variedade de processamentos utilizados industrialmente.

Embora o impacto da alteração estrutural das proteínas lácteas nas propriedades tecno-funcionais dos alimentos (viscosidade, etc.) seja conhecido, o entendimento do seu efeito nas propriedades funcionais (alegações à saúde) desses alimentos ainda está em construção. É consenso que as matrizes alimentares não são inertes a adição de compostos bioativos, ainda assim, este fato é ignorado durante o desenvolvimento de alimentos funcionais, geralmente fundamentado na simples incorporação desses compostos nos alimentos. Para balizar o desenvolvimento de alimentos funcionais e garantir os efeitos benéficos associados, é crucial entender como as alterações estruturais induzidas às matrizes alimentares proteicas afetam a atividade biológica dos compostos bioativos. Neste contexto o presente projeto de pesquisa propõe uma estratégia de engenharia reversa para gerar conhecimento que permita prever o comportamento de carotenoides em matrizes proteicas submetidas a diferentes processamentos industriais. Por meio da associação de resultados obtidos em matrizes reais e modelo almeja-se estabelecer regras genéricas para o comportamento (interação / atividade biológica) de carotenoides em matrizes multi proteicas complexas. Além da comunidade científica, o conhecimento gerado pela presente proposta interessará também empresas da área de alimentos/ingredientes funcionais, bem como órgãos de regulamentação.

MICROESTRUTURA DE PRODUTOS LÁCTEOS

A tecnologia de alimentos pode ser definida como uma tentativa controlada para preservar, transformar, criar ou destruir uma estrutura que foi transmitida pela natureza ou pelo processamento. Atualmente existem inúmeras ferramentas de caracterização disponíveis para sondar a estrutura dos alimentos visando racionalmente projetar processos que melhorem a qualidade dos produtos.

Uma característica de interesse para a solução de problemas e falhas atualmente em evidência, está na identificação e caracterização das micro e nanoestruturas do leite e derivados. A figura 1A apresenta de forma resumida os principais componentes do leite organizados pelo tamanho médio dos seus raios hidrodinâmicos, enquanto a figura 1B apresenta as principais estruturas do leite e também dos ingredientes e partículas mais comumente empregadas e encontradas na tecnologia de processamento dos derivados lácteos.

Figura 1: caracterização das micro e nanoestruturas do leite e derivados: (A) diâmetros hidrodinâmicos médios das principais estruturas presentes no leite em micrômetros; (B) principais partículas encontradas nos derivados lácteos

O ar ocluso nas partículas atomizadas afeta diretamente na qualidade final do leite em pó, como, por exemplo, baixa densidade volumétrica e formação de finos. A incorporação de ar no concentrado ocorre em vários pontos, e quanto maior a habilidade espumante, maior a capacidade de incorporar ar atmosférico.

Durante a secagem, existe um aumento da concentração de sólidos, da viscosidade e tensão superficial das partículas, formando uma camada na parte externa que dificulta a difusão. Isto se torna mais pronunciado à medida que se desenvolve a secagem e quando a umidade das partículas atinge ao redor de 10% a 20%, que é o chamado “ponto crítico de umidade”, a temperatura das partículas aumenta gradualmente conforme a secagem. Porém, se a temperatura do ar que envolve as partículas for suficientemente alta, poderá ocorrer superaquecimento, desnaturando a proteína, que influencia na inadequada solubilização do leite em pó e no endurecimento da lactose amorfa que impede a difusão de vapor. Dessa forma, permanecendo vapor e ar em seu interior, as partículas se expandem fazendo pressão na camada externa, inchando como uma esfera oca com espessura da camada ao redor de 1 micrômetro, ocorrendo, em alguns casos, explosões, conforme apresentado na figura 2.

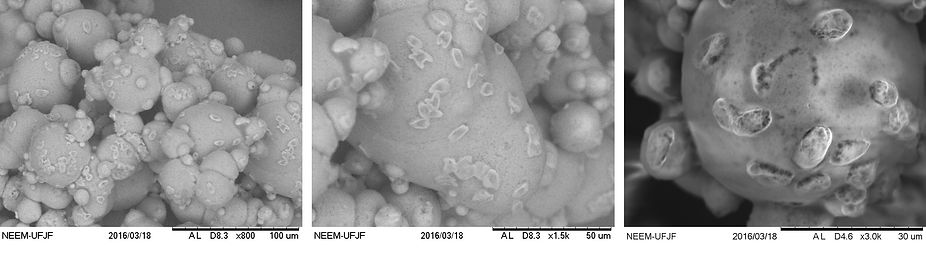

Figura 2: Dados morfológicos de leite em pó integral, com presença de partículas com características de explosões.

Outra aplicação extremamente útil das técnicas se refere à caracterização de produtos desidratados. Na superfície das partículas de leite em pó integral encontram-se pequenos glóbulos de gordura que não estão protegidos pela membrana lipoproteicas, chamada gordura livre, o que pode causar problemas, como, por exemplo, rancificação do produto quando armazenado por muito tempo, aglomeração das partículas e dificuldade de reconstituição.

Conforme demonstrado na figura 3, a ineficiência do processo de homogeneização do leite concentrado visando a produção de leite em pó integral, apresentou influência direta na quantidade de gordura livre, que tende a envolver células de ar nas partículas do leite em pó ou formar “erupções” na superfície das mesmas, promovendo oxidação e até aglomeração do pó

Figura 3: Dados morfológicos da superfície de partículas de leite em pó integral, com presença de migração de gordura livre, ocasionada por ineficiência do processo de homogeneização do leite concentrado, gerando aglomeração no produto. .

O prazo de validade dos produtos lácteos desidratados é geralmente estabelecido para garantir a segurança microbiológica e para manter aceitáveis as características sensoriais. Apesar de ser microbiologicamente estável, mudanças físicas e químicas, como a cristalização da lactose, aglutinação de partículas, oxidação de gordura, reação de Maillard e reações enzimáticas podem ocorrer durante o armazenamento, modificando as propriedades físico-químicas e funcionais do produto.

Nas últimas décadas, os métodos espectroscópicos, juntamente com as ferramentas quimiométricas, têm sido aplicados para avaliar a qualidade de produtos lácteos como uma alternativa para os procedimentos tradicionais. A figura 4A mostra o espectro Raman do WPC produzido em condições ideias, 4B WPC produzido em condições ideais e armazenado durante 6 semanas em condição ambiente e 4C α-lactose monohidratada.

As modificações que ocorrem nos espectros Raman das amostras armazenadas em condição ambiente são provocadas, principalmente, pelo aumento na quantidade de água no pó. Quando o WPC é exposto à umidade relativa alta, o pó absorve água e há um aumento da concentração desta no alimento. Como consequência, ocorre uma diminuição da viscosidade e aumento da mobilidade molecular. Esses dois fatores determinam uma série de modificações estruturais dependentes do tempo, tais como: gomosidade, colapso e cristalização dos componentes amorfos, que diminuem a vida útil do WPC e, por consequência, a sua qualidade.

Figura 4: Espectros Raman do WPC produzido em condições ideias (A), WPC produzido em condições ideais e armazenado durante 6 semanas em condição ambiente (B); α-lactose monohidratada (C).

Outra técnica para investigação da microestrutura de produtos em pó, usada durante o processo de reidratação é a análise de tamanho de partículas por difração laser sendo muito empregada em diversos ramos industriais devido à sua facilidade de operação, rapidez e amplitude de leitura.

A figura 5 mostra, para cada amostra de leite em pó integral com diferentes características de aglomeração e processo de fabricação, a distribuição do percentual do volume ocupado pelas partículas (durante o processo de reidratação em água) de acordo com os seus diâmetros hidrodinâmicos. Tipicamente, a distribuição de tamanho de partícula de leite fluido integral mostra duas populações, um correspondendo às micelas de caseína (centradas em torno de 150-200 nm) e uma outra correspondente aos glóbulos de gordura (centradas em torno de 5 µm). Todas as amostras apresentam uma população de partículas centrada a aproximadamente 200 nm, que correspondem às micelas de caseína como no leite fluido. A intensidade desta população depende diretamente da qualidade da microestrutura do pó.

Figura 5: Distribuição do tamanho das partículas de leites em pó com diferentes características de microestrutura durante o processo de reidratação: A (□), B (○), C (Δ), D (◊) e E (●).